Leader in Microprocessing and Shaping Instruments

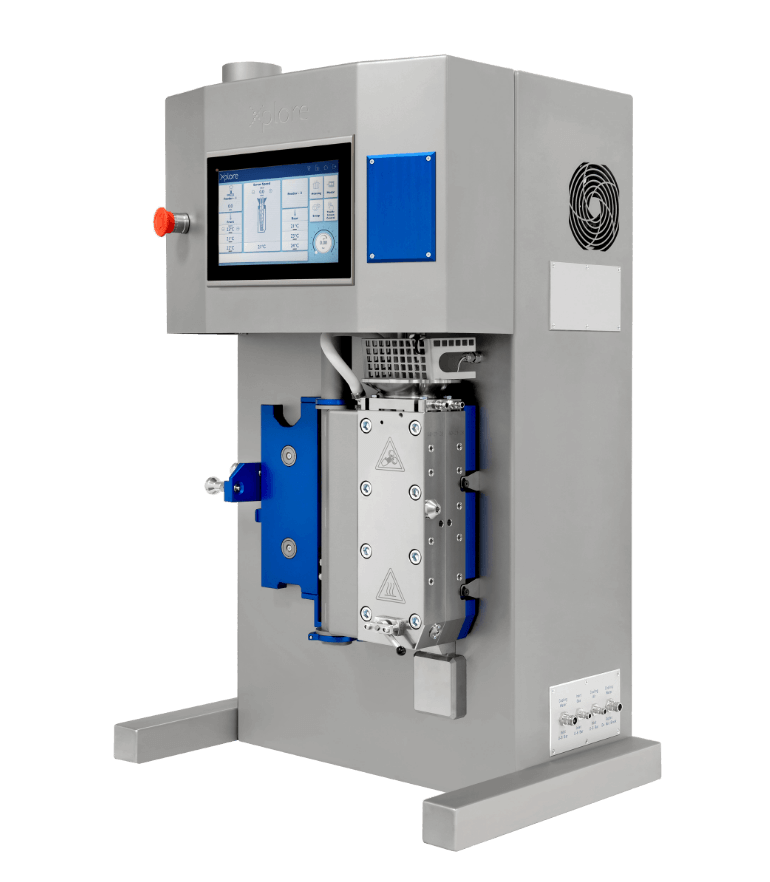

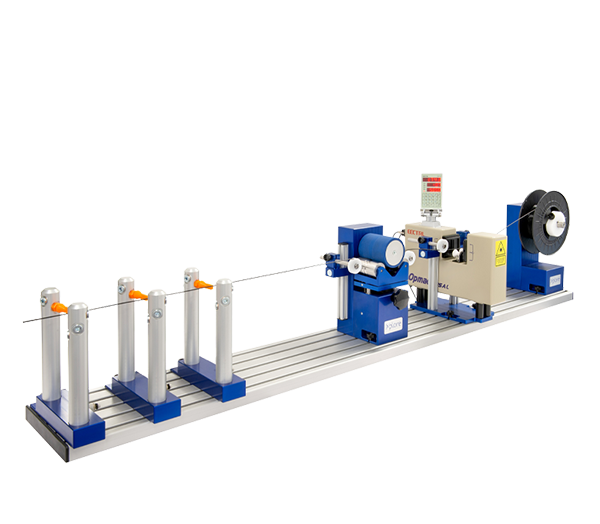

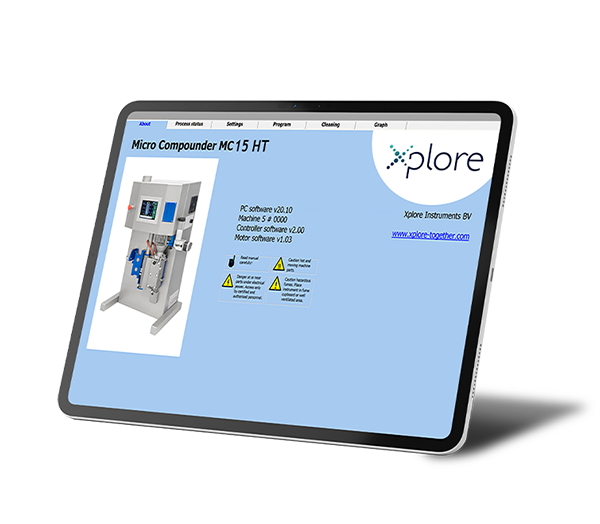

Xplore pioneers high-quality, reliable microprocessing and shaping instruments for cost-efficient, faster R&D and shorter time-to-market. Our bench-top Micro-Compounders replicate large twin-screw compounders, offering precise control over temperature, mixing intensity, and time. With 2 ml to 40 ml sample volumes, researchers can quickly produce test samples, reducing material costs and R&D time. Designed for fume cupboard use, they enhance operator safety by minimizing exposure to hazardous materials. Our shaping instruments, including injection molders, fiber lines, cast film lines, and a 3D filament line, seamlessly integrate with Xplore and other extruders, ensuring efficient material shaping. Key Benefits are lower material consumption & costs, reduced environmental impact & contamination, enhanced operator safety, and compact, space-efficient design. Xplore’s solutions enable efficient, precise, and scalable material development, accelerating innovation and R&D success.

Key Features

- High-quality fast results: well mixed relevant rheological data.

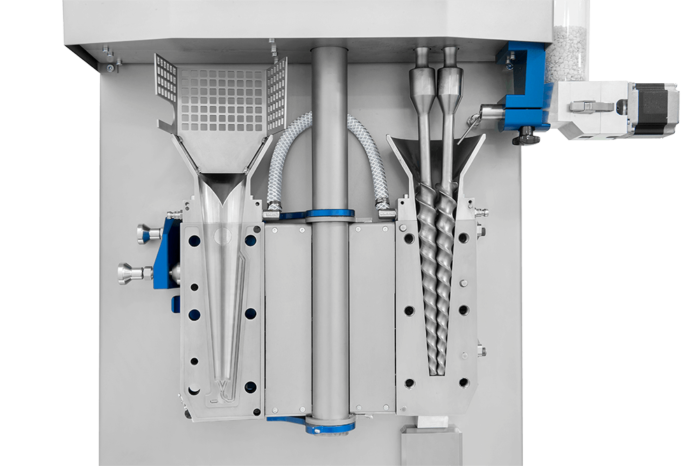

- Reliable, reproducible, repeatable. Two times three separate heating zonesoffer perfect control of the process temperature. An abrasion and chemicalresistant barrel that is fluid-tight generates reproducible processing andrheological data over many years.

- Excellent mixing reduces the processing time and easy to clean; hence,minimizes turnaround time between batches.

- Sample volumes range from 2 ml* to 15 ml and recently 40 ml toenable earlier testing and reduce screening costs. Quick exchange of samplesand screws to run different experiments in a short turnaround time frame.Recirculation channel length, process time, mixing and dispersion parametersfor different formulations and tests can be chosen at will.