Melt spinning of fibers

Published: September 4, 2025 · Reading time: 4 minutes

Introduction

Polymer fibers are central to countless applications, from textiles and composites to filtration and biomedical materials. Their performance is largely determined not only by the polymer used, but also by the way the fibers are processed. Melt spinning and subsequent drawing are two critical steps that govern fiber morphology, orientation, and properties. In the melt spinning process, a polymer is heated above its melting temperature and extruded through small capillaries in a spinneret or die, forming thin filaments. These filaments are rapidly cooled (typically by quench air or contact cooling) to solidify the polymer. The balance between extrusion rate, cooling conditions, and winding speed determines the initial structure of the as-spun fibers.

Fiber making polymers

Not all polymers can form usable fibers. Good fiber-making polymers combine melt processability with the ability to crystallize and orient under drawing. Some of the most widely used families include:

- Polyesters (e.g., PET, PBT): High strength, excellent dimensional stability, widely used in textiles, tire cords, and packaging.

- Polyamides (e.g., Nylon 6, Nylon 6,6): Toughness, abrasion resistance, and high crystallinity make them ideal for technical textiles, carpets, and engineering fibers.

- Polyolefins (e.g., polypropylene, polyethylene): Lightweight, chemically resistant, and cost-effective, often used in nonwovens, ropes, and geotextiles.

Beyond conventional textiles, there is a growing need for fibers that can withstand extreme conditions in aerospace, automotive, medical, and electronics applications. This is where high-performance engineering polymers come into play:

- Poly(ether ether ketone) (PEEK), Polyaryletherketone (PAEK): Exceptional mechanical strength, thermal stability above 250 °C, and chemical resistance. Used in high-performance composites and medical devices.

- Liquid crystalline polymers (LCPs): Intrinsically ordered structures that produce ultra-strong, stiff, and heat-resistant fibers.

- Poly(phenylene sulfide) (PPS): Excellent thermal stability and chemical resistance, used in filtration, protective textiles, and composites.

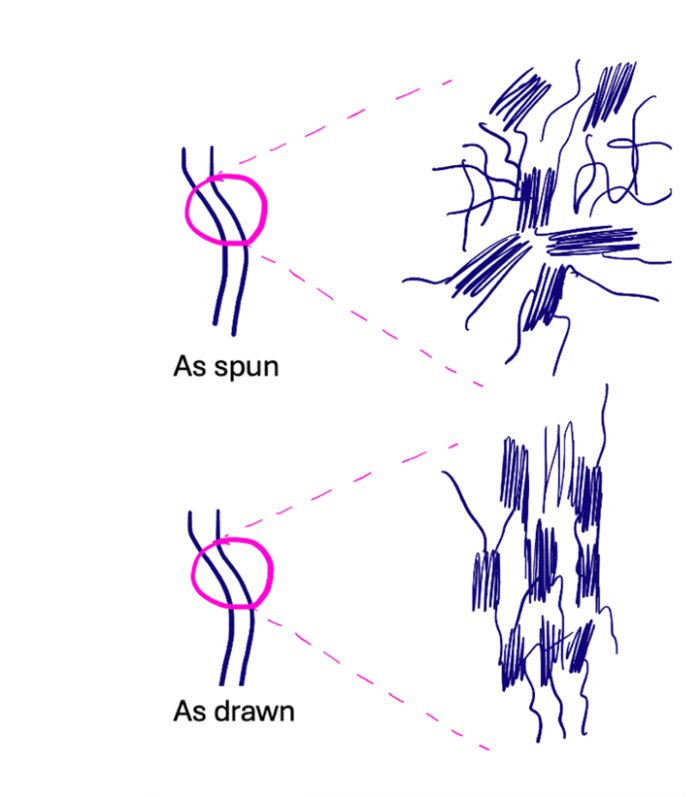

Spun vs. Drawn

Freshly spun fibers typically exhibit low molecular orientation, since the polymer chains are largely disordered right after extrusion. Their crystallinity is limited because rapid cooling can trap the material in an amorphous state, and their diameter is relatively coarse, being governed mainly by extrusion conditions and take-up speed. To enhance these properties, fibers undergo a drawing process, where they are stretched under controlled temperature. Drawing aligns the polymer chains along the fiber axis, increases crystallinity, and reduces fiber diameter. As a result, fibers achieve higher tensile strength and modulus from improved chain orientation, greater dimensional stability through enhanced crystallinity, and become finer with smoother surfaces. For example, drawing can increase the tensile strength of polyester or nylon fibers several times compared to their as-spun state (Table 1). A typical illustration is shown in Figure 1.

Table 1. Comparison of spun vs. drawn fibers

| Property | As-Spun Fiber | Drawn Fiber |

| Chain orientation | Low | High |

| Crystallinity | Limited | Enhanced |

| Mechanical strength | Weak, extensible | Strong, stiff |

| Fiber diameter | Larger, less controlled | Reduced, more uniform |

| Applications | Precursors, disposable use | Technical textiles, composites |

Figure 1. Schematic illustration of the morphological changes in the structure of a fiber before and after drawing

Lab-scale fiber spinning

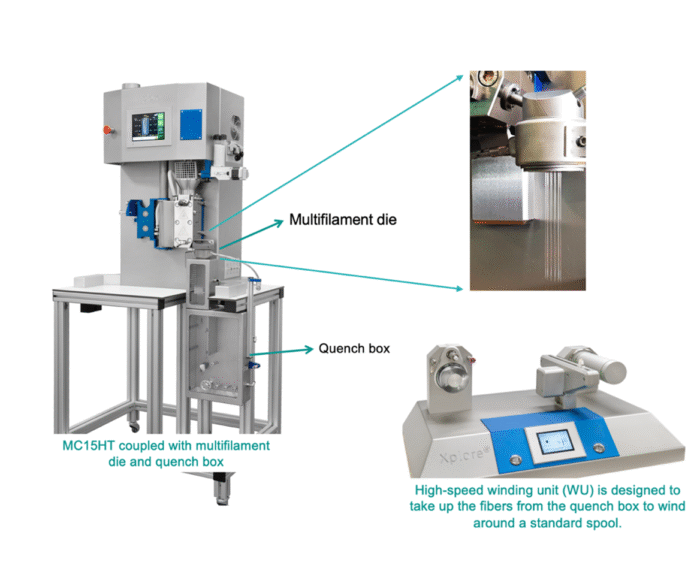

Benchtop fiber spinning systems replicate the fundamentals of industrial melt spinning on a laboratory scale, enabling controlled investigation of polymer processing-structure-property relationships. In these setups, polymer pellets or powders are melted and extruded through a spinneret to form filaments, which are then solidified by quenching and further processed by winding and drawing. Key variables such as spinning temperature, spinning rate, quench conditions, and take-up speed govern chain orientation, crystallization kinetics, and final fiber morphology. With precise control and minimal material requirements, benchtop systems are essential for studying new polymers, nanocomposites, and high-performance fibers, while providing accurate insights into industrial fiber manufacturing. Studying and optimizing these processes at laboratory scale is made possible with systems like the Xplore Microfiber Line (Figure 2).

- The Multifilament or Monofilament Die enables authentic fiber spinning using just a few grams of material.

- The Winder Unit allows precise control of take-up speed (1–600 m/min), which directly influences the orientation of as-spun fibers.

- The Conditioning/Stretching Unit provides controlled drawing of fibers, with adjustable temperatures and stretching ratios to tune final properties.

- The high-temperature range (up to 475 °C) ensures processing of engineering plastics and high-performance polymers.

Figure 2. Xplore Micro Fiber line a.) Spinning and winding units, b.) Conditioning/stretching unit

This benchtop setup reproduces industrial spinning and drawing conditions while minimizing material consumption, making it ideal for research on new fiber-making polymers, reinforced fibers, polymer blends for fiber applications, or fiber precursors.

Conclusion

The performance of polymer fibers is not solely dictated by the base material but is critically shaped by processing steps such as melt spinning and drawing. While as-spun fibers form the foundation, it is the drawing process that unlocks their full potential by enhancing orientation, crystallinity, and mechanical strength. Laboratory-scale systems like the Xplore Micro Fiber Line provide powerful tools to replicate industrial conditions with minimal material, enabling the development of advanced fibers from conventional polymers to high-performance engineering materials. Ultimately, mastering both material selection and processing pathways is key to producing fibers tailored for demanding applications in textiles, composites, filtration, and beyond.