Understanding Cast and Blown Film Technologies in Polymeric Film Processing

Published: September 11, 2025 · Reading time: 6 minutes

Introduction

Polymeric films are indispensable in modern life. From the transparent packaging that protects food to the sterile barrier materials used in medical devices and the flexible substrates in electronics, films made from polymers enable innovation across various industries. Their performance depends not only on the polymer chemistry but also on the method of film processing. Among the most widely used methods are cast film extrusion and blown film extrusion, each with unique characteristics, strengths, and limitations.

This article introduces the fundamentals of film processing, compares cast and blown film technologies, explores the role of orientation in cast films, and finally highlights how Xplore Instruments’ cast film lines, particularly the Proline system, can help researchers and product developers’ study and optimize films at a benchtop scale.

Cast Film versus Blown Film

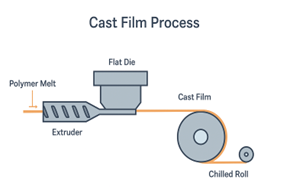

Film extrusion is the dominant process for producing polymer films. While both cast and blown film methods rely on melting, extruding, and solidifying a polymer, the way the molten polymer is shaped and cooled makes a big difference.

Advantages of cast film include:

- Excellent clarity and optical properties due to rapid cooling.

- Uniform film thickness and smooth surfaces.

- Precise process control, making it ideal for specialty films.

- High productivity in wide film production.

However, cast films are typically uniaxially oriented (mainly in the machine direction) and can lack the toughness and balanced mechanical properties of blown films.

Blown Film Extrusion

Blown film processing, by contrast, involves extruding the molten polymer through a circular die to form a tube. Air is then blown into the tube, inflating it like a bubble. As the bubble rises, it cools while being stretched in both the machine and transverse directions, before being collapsed and wound.

Advantages of blown film include:

- Biaxial orientation, giving balanced mechanical strength.

- Excellent toughness and puncture resistance.

- Versatility for producing narrow-width films.

- High suitability for packaging applications, including multilayer barrier films.

The trade-off is that blown films often show less clarity than cast films due to slower cooling and can be more challenging to control precisely in terms of gauge uniformity.

Figure 1. (A) Cast film extrusion (B) Blown film extrusion

Applications of Polymeric Films

Polymeric films are everywhere. Some of the most significant application areas include:

- Packaging: Flexible packaging for food, beverages, pharmaceuticals, and consumer goods relies heavily on both cast and blown films. Clarity, barrier properties, and toughness are key.

- Medical and Pharmaceutical: Sterile barrier films, breathable membranes, and biocompatible films are used in devices, wound dressings, and drug packaging.

- Electronics: Thin, flexible polymer films act as insulating layers, protective barriers, or substrates for printed electronics.

- Agriculture: Films are used in greenhouses, mulching, and soil covers, where mechanical durability and UV resistance are critical.

- Technical Films: Specialized membranes for filtration, composites, and energy applications.

The diversity of end uses makes it clear why understanding processing–property relationships is vital for innovation.

Orientation in Cast Films

One of the most important aspects in film processing is orientation, the alignment of polymer chains and crystalline domains that develops during stretching and cooling. Orientation significantly influences mechanical, optical, and barrier properties.

In cast films, orientation is mainly in the machine direction (MD), because the film is drawn as it is taken up on rolls. By adjusting the draw ratio (the relative speed between extrusion and take-up), processors can control the degree of orientation.

- Higher draw ratios generally improve tensile strength and stiffness in the MD, but can reduce elongation.

- Optical properties such as haze and gloss are affected by orientation and cooling rate.

- Barrier performance (to gases or moisture) can also be tuned by modifying orientation and crystallinity.

For research and development, being able to precisely control and study orientation at small scales is critical. This is especially true when testing new polymer formulations, blends, or composites where only limited material may be available.

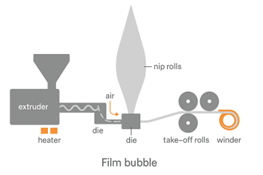

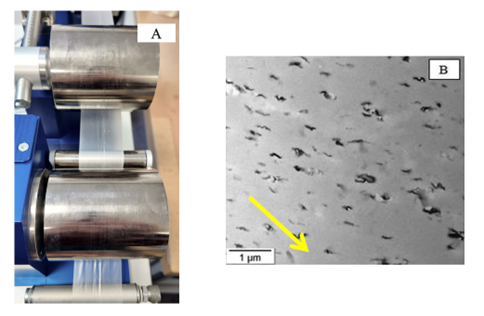

Xplore’s cast film lines are compact extrusion systems that replicate the essentials of industrial cast film production; polymer melt extrusion through a flat die, rapid quenching on a chilled roll, and controlled take-off; while operating at laboratory scale. They are designed to work with tiny material quantities, making them particularly valuable for research and development where new polymers, blends, or additives are available only in limited amounts. The lines offer precise control of processing parameters such as extrusion temperature, chill roll speed, and draw ratio, enabling systematic studies of how processing influences film thickness, surface quality, and reproducibility.

Beyond simply producing films, these benchtop systems provide a practical way to link processing conditions to film performance. Importantly, even at small scale the process introduces orientation of polymer molecules in the machine direction as the molten film is drawn and cooled. This orientation has a significant impact on film properties: higher draw speeds typically increase tensile strength and stiffness in the extrusion direction but may also reduce elongation at break. Additionally, optical clarity, gloss, and barrier characteristics can change with the degree of alignment. In addition to polymer chain orientation, fillers or reinforcing particles within the formulation may also align during processing, further influencing mechanical anisotropy and functional performance. By allowing researchers to explore both formulation and processing effects with minimal waste, Xplore’s cast film lines make it possible to understand how orientation of both polymers and fillers, determines the final performance of polymer films.

Figure 2. (A) Cast film proline of Xplore Instruments (B) Oriented clay particles through machine direction (yellow arrow shows the machine direction) in a bio-polyester matrix

Case Study Highlights

At Xplore, we have examined the effects of processing parameters on the properties of LLDPE films in machine and transverse directions. For this purpose, we have cast two films using different processing conditions (PC1 and PC2, see Table 1). At PC1, since the melt temperature was lower under the same casting die temperature and stretching rate, the polymer’s melt strength (melt viscosity) was higher, which resulted in a higher degree of orientation. As a result, the tensile strength and elongation at break in the machine direction were higher. On the contrary, the transversal properties were lower compared to those of PC2.

Table 1. Processing conditions

| Barrel/Die Temperature | Line Speed | Die Thickness | |

| PC1 | 190oC | 50 cm/min | 0.4 mm |

| PC2 | 235oC | 50 cm/min | 0.4 mm |

Table 2. Properties of LLDPE films prepared at two different conditions

| Machine Direction | Transverse Direction | ||

| PC1 | Tensile Strength (MPa) Elongation at Break (%) | 35.5 (±) 2.5 650 (±) 15 | 29.6 (±) 2.3 355 (±) 22 |

| PC2 | Tensile Strength (MPa) Elongation at Break (%) | 28 (±) 1.8 590 (±) 23 | 21 (±) 2.2 325 (±) 15 |

Conclusion

Polymeric films are vital materials with broad industrial and societal importance. Cast and blown film extrusion are complementary technologies that provide distinct advantages, clarity and uniformity in cast films, versus toughness and biaxial strength in blown films. Among these, cast films are susceptible to orientation, making them a rich area for R&D.

Xplore Instruments’ Cast Film Proline enables researchers to investigate these phenomena at a benchtop scale, with minimal material consumption and maximum flexibility. By combining compact design, precision control, and integration with compounding workflows, the Proline system empowers R&D teams to move faster, waste less, and innovate more effectively.

For academics and industrial developers alike, this represents a decisive step toward smarter, more agile film processing research, bringing the path from concept to data within reach of every laboratory.