How are Flame-Retardant Thermoplastics evolving, and what role do Micro-Compounders play?

Published: September 25, 2025 · Reading time: 3 minutes

Introduction

Thermoplastics are the backbone of modern industries, from consumer electronics and automotive parts to cables, textiles, and construction materials. Their versatility, ease of processing, and recyclability make them indispensable. However, one critical limitation persists: flammability. Most thermoplastics ignite easily, spread flames quickly, and release toxic smoke, posing significant risks in high-demand applications where fire safety is non-negotiable.

Why Do Polymers Need Flame Retardants?

Polymers are hydrocarbons at their core, meaning they are inherently combustible. When exposed to heat or flame, their long chains break down, releasing flammable gases that sustain burning. Without modification, many widely used polymers would not meet the strict safety requirements for use in transportation, electronics, or building materials.

For example:

– Polyethylene (PE): One of the most common plastics, used in films, packaging, and insulation. PE burns rapidly, dripping molten polymer and propagating flames, making it unsuitable for safety-critical applications without flame retardants.

– Polyvinyl chloride (PVC): In contrast, PVC contains chlorine in its structure, which naturally suppresses combustion and reduces flammability. While PVC shows relatively higher flame resistance compared to PE, it can still release toxic hydrogen chloride gas during burning.

This comparison illustrates why many polymers require external flame retardant additives or chemical modifications to achieve both fire safety and regulatory compliance.

How Flame Retardancy is Characterized

Before new formulations are adopted, their flame retardancy is rigorously evaluated using internationally recognized test methods:

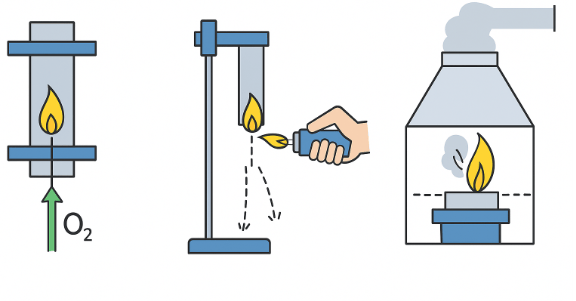

Figure 1. From left to right – Limiting Oxygen Index (LOI), UL-94, and Cone Calorimetry.

Recent Research Trends in Flame Retardant Thermoplastics

1. Halogen-Free Solutions

– Growing regulatory and environmental pressure has accelerated the replacement of brominated systems with phosphorus-, nitrogen-, and silicon-based FRs.

– Recent reviews highlight the effectiveness of phosphorus flame retardants in polyamide-6 and -66, TPU, and polyester systems.

2. Nanostructured Flame Retardants

– Metal–organic frameworks (MOFs), nanoclays, graphene, and LDHs provide barrier effects and protective char layers.

– They enable reduced additive loadings while improving mechanical and thermal stability.

3. Bio-Based and Sustainable Additives

– Renewable FRs (lignin, starch derivatives, natural polyphenols) align with circular economy goals and reduce toxicity.

– Research is advancing in biopolymer-based FR systems, particularly for packaging and textiles.

4. Reactive Extrusion Approaches

– Advances in reactive extrusion allow direct incorporation of FR groups into polymer chains, producing intrinsically flame-retardant thermoplastics.

5. Multifunctional Systems

– Modern FR systems target fire safety + mechanical reinforcement + recyclability simultaneously.

– Hybrids combining phosphorus, nitrogen, and nanofillers are especially promising.

How Microcompounders Accelerate Flame Retardant Development

Micro-compounders, miniaturized twin-screw extrusion systems, are revolutionizing FR compound development. Their unique advantages include:

– High Filler Handling: Ability to process highly filled systems with FR powders, fibers, or nanomaterials.

– Precise Temperature Control: Essential for heat-sensitive FR additives such as phosphates or bio-sourced systems.

– Shear Tuning & Residence Time Control: Tailored dispersion of nanoparticles and prevention of additive degradation.

– Rapid Prototyping: Small batch sizes allow quick screening of multiple FR formulations with minimal material waste.

– Post-Shaping Integration: Compatibility with injection molding, film blowing, fiber spinning, or cable coating for direct end-use evaluation.

By combining precise control with flexibility, microcompounders provide a powerful bridge from lab-scale research to industrial-scale applications.

Conclusion

The field of flame-retardant thermoplastic compounds is undergoing a sustainable and performance-driven transformation. The focus is shifting toward halogen-free, nanostructured, and bio-based systems, supported by advanced testing methods like LOI, UL-94, and cone calorimetry. Microcompounders empower researchers and developers to prototype, refine, and validate FR thermoplastics faster and with greater precision, accelerating innovation in industries where safety, performance, and sustainability must converge.