Why Do Polymers Degrade During Extrusion and How Can You Limit It?

Published: October 16, 2025 · Reading time: 3 minutes

Introduction

When polymers are melted and mixed inside an extruder, they undergo intense thermal and mechanical stress. While this is essential for shaping, blending, or compounding materials, it also exposes them to an invisible threat: thermo-oxidation. Thermo-oxidation is the chemical degradation of polymers due to combined effects of heat and oxygen. During extrusion, molten polymers are exposed to:

- High temperatures (typically 180-450°C),

- Mechanical shear (generating additional frictional heat),

- Air/oxygen (especially at feed and die zones).

This causes chain scission, crosslinking, increase in carbonyl index, loss of molecular weight, and property deterioration. The results can be serious: loss of gloss, discoloration, a burnt odor, lower viscosity, and ultimately poor mechanical performance. Understanding and preventing thermo-oxidation is therefore a central goal in polymer engineering, especially as the industry transitions toward recycled and bio-based feedstocks that are often more sensitive to heat and oxygen.

Stabilizing Polymers Before They Degrade

At high temperatures, polymer chains can generate free radicals, reactive fragments that quickly combine with oxygen to form peroxides. These peroxides, in turn, decompose into more radicals, creating a self-accelerating chain reaction. Once it begins, the process can propagate even if the material cools down, leading to long-term instability or premature aging.

To prevent this, formulators rely on antioxidants, specialized molecules that interrupt the radical chain mechanism. There are two main categories:

- Primary antioxidants, such as hindered phenols (e.g., Irganox 1010), neutralize radicals directly.

- Secondary antioxidants, such as phosphites (e.g., Irgafos 168), convert hydroperoxides into stable, non-reactive products.

When used together, these stabilizers provide synergistic protection: the secondary antioxidants handle the early oxidative products, while the primaries capture residual radicals. This pairing remains the cornerstone of polymer stabilization in extrusion and injection molding.

Recent research by Markus et al. [1,2] utilized Xplore MC15 HT micro-compounders to test bio-based stabilizers in polypropylene. The team tracked oxidation via DPPH assays and rheological changes over multiple extrusion passes. Results showed that natural stabilizers can match or surpass conventional additives, all tested on just a few grams of material, demonstrating how Xplore systems enable efficient, sustainable additive screening.

Engineering Solutions to Oxygen and Heat Exposure

Thermo-oxidation isn’t just a chemistry problem, it’s an engineering one. Polymer degradation can be minimized through design choices in conventional extrusion equipment:

- Sealed feed zones prevent oxygen intake with the polymer feed.

- Vacuum or inert-gas vents remove trapped gases and volatiles during processing.

- Precise temperature zoning avoids hot spots that accelerate oxidation.

- Optimized screw geometry controls shear stress and heat generation.

- Polished surfaces and flow-optimized barrels eliminate stagnation points where material can degrade.

Precision Control on a Micro Scale with Xplore Systems

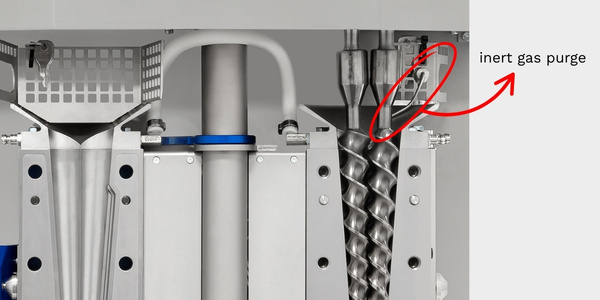

Xplore micro-compounders are engineered for precision, low-volume processing, ideal for sensitive polymers like PA, PET, PBT, and PHBV. The system’s small melt volume and short residence time (often just a few minutes) inherently reduce thermo-oxidation risk. For enhanced protection, users can also integrate inert gas purging (nitrogen or argon) into the top hopper (Fig.1), replacing ambient air, a feature rarely available in conventional bench-scale extruders.

Figure 1. Inert gas purge in Xplore Micro-Compounders

Why Thermo-Oxidation Control Matters More Than Ever

As sustainability drives polymer innovation, materials face greater oxidation challenges. Recycled polymers, in particular, often contain impurities or residual additives that accelerate degradation during reprocessing.

Xplore micro-compounders provide a platform to:

- Evaluate new stabilizer systems,

- Simulate multi-pass recycling,

- Optimize formulations for durability,

- Reduce time, waste, and material usage in R&D.

By merging robust engineering, exacting control, and micro-scale efficiency, Xplore transforms thermo-oxidation from a problem into a quantitative research opportunity, accelerating the journey from lab-scale insight to industrial impact.

References

- Markus K, Metzsch-Zilligen E, Pfaendner R. Radical scavenging and processing stability of novel biobased stabilizers in polypropylene. Polymer Degradation and Stability. 2024; 222: 110709.

- Markus K, Kirschbaum T, Metzsch-Zilligen E, Pfaendner R. Processing stability and radical scavenging efficiency of novel biobased stabilizers: Insights from long-term extrusion and DPPH assays. Polymer Degradation and Stability. 2025; 233: 111162.