How to Control Residence Time in Conventional Extrusion?

Published: October 30, 2025 · Reading time: 3 minutes

Introduction

In polymer extrusion and compounding, residence time is one of the most important yet often underestimated processing parameter. It represents the average time a material spends inside the extruder, from feeding to exiting through the die. Mastering residence time control is key to achieving stable processing conditions, uniform melt quality, and consistent final material properties.

What Is Residence Time?

When polymer pellets, powders, or blends enter an extruder, they experience heat, shear, and pressure. During this process, the material melts, mixes, and homogenizes before being shaped into the final product. The residence time describes how long the material remains inside the extruder, determining the extent of thermal and mechanical treatment it undergoes.

Not all material elements spend the same time inside the barrel. Some flow quickly through the screw channels, while others stay longer in slower regions. This variation is described by the residence time distribution (RTD). A narrow RTD indicates uniform flow and consistent melting, whereas a broad RTD suggests uneven heating or mixing, often a sign of unstable processing (Fig. 1).

Figure 1. Determination of Residence Time Distribution – Example Study Performed with Xplore Micro-Compounder

Why Residence Time Matters

Residence time directly affects the thermal history, viscosity, and mechanical performance of the processed polymer.

- Too short residence time can lead to incomplete melting, poor additive dispersion, and visible product defects.

- Too long residence time may cause thermal degradation, crosslinking, or chain scission, leading to colour difference, loss of strength, or viscosity changes.

Optimizing residence time ensures the material receives just enough thermal and shear energy for proper homogenization without compromising its molecular integrity.

How to Control Residence Time in Extrusion

Several factors influence residence time and its distribution:

- Screw Speed: Higher speeds reduce residence time by moving material faster through the barrel.

- Feed Rate: Increasing feed rate slightly extends residence time by filling the screw channels more completely.

- Screw Design and L/D Ratio: Longer screws and complex mixing elements modify the flow pattern and RTD.

- Temperature Profile: Elevated temperatures lower melt viscosity, allowing faster flow and shorter residence times.

- Die Resistance: A restrictive die increases back pressure and prolongs residence time.

To evaluate these effects, engineers often use tracer tests, injecting a detectable compound at the feed zone and tracking its concentration at the die, to measure the RTD experimentally.

Impact on Final Properties

The residence time ultimately shapes melt homogeneity, color stability, molecular weight distribution, and surface finish. In reactive or filled systems, it also affects chemical conversion and dispersion quality. In short, residence time links the internal dynamics of the extruder to the external performance of the final product.

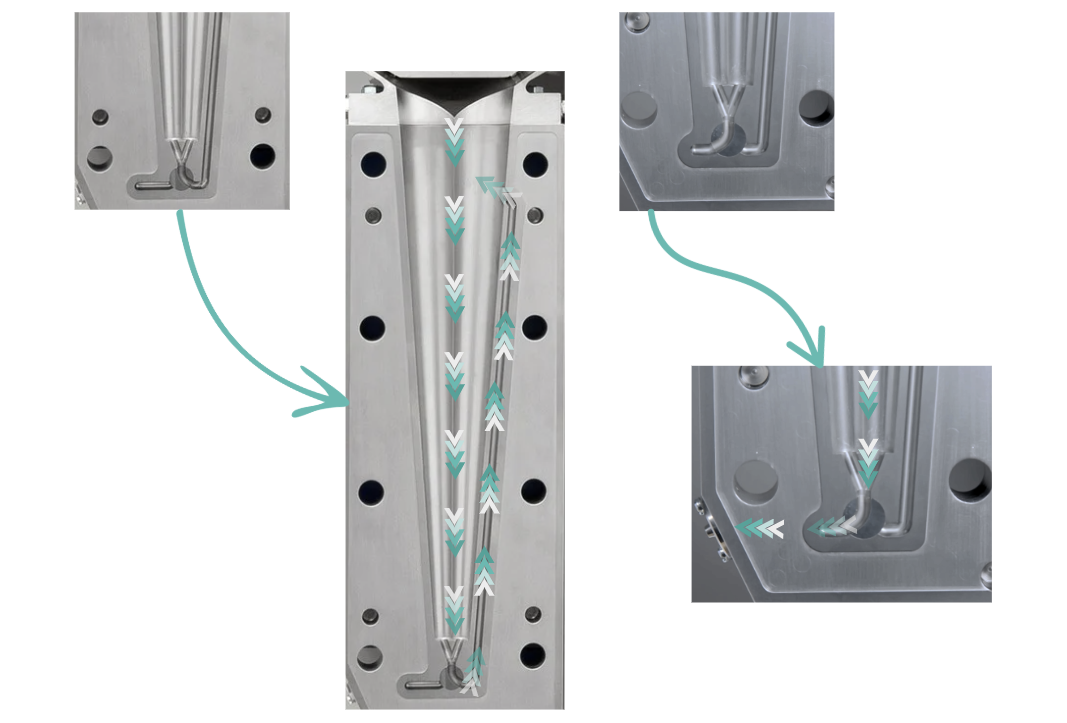

Tunable Residence Time with Batch Micro-Compounding

Using Xplore’s batch micro-compounding technology, users can precisely define and control the residence time, ensuring reproducible processing and material properties. The molten polymer continuously circulates through a recirculation channel, where a large fraction of material is constantly exposed to shear forces, ensuring efficient mixing and dispersion. When the valve kept closed, the system behaves like an extruder with an infinitely long length-to-diameter (L/D) ratio, allowing extended residence times under fully controlled conditions. Once the valve is opened, the defined residence time ends, and the melt is directed toward the die for extrusion. In this way, residence time in batch mode is accurately governed by the valve position, offering a unique tool for studying how processing time influences melt homogeneity, dispersion, and final polymer properties (Fig. 2).

Figure 2. Recirculation valve positions a) Valve is closed b) Valve is open

Conclusion

Residence time is a fundamental parameter in polymer extrusion and compounding, influencing melt uniformity, dispersion, and final material properties. Understanding how process variables affect residence time enables better control over product quality and consistency. With Xplore’s batch micro-compounding technology, residence time can be precisely tuned, offering a powerful tool for studying and optimizing polymer processing.