How Overmolding & Insert molding Merges Strength and Softness into a Single Functional Part?

Published: November 13, 2025 · Reading time: 5 minutes

Introduction

In modern product design, functionality and aesthetics often need to coexist within a single part. Overmolding is a key polymer-processing technique that enables this integration. It involves molding one material; typically a soft or functional polymer; over a pre-formed substrate, resulting in a single, inseparable composite structure. The process combines mechanical strength, comfort, and performance while reducing the need for secondary assembly steps such as gluing or mechanical fastening.

What Is Overmolding?

Overmolding is a multi-step injection molding process where a base material (the substrate) is partially or completely covered by a second polymer (the overmold). The result is a single composite part with an intimate bond between layers. Depending on the setup, this can be achieved through:

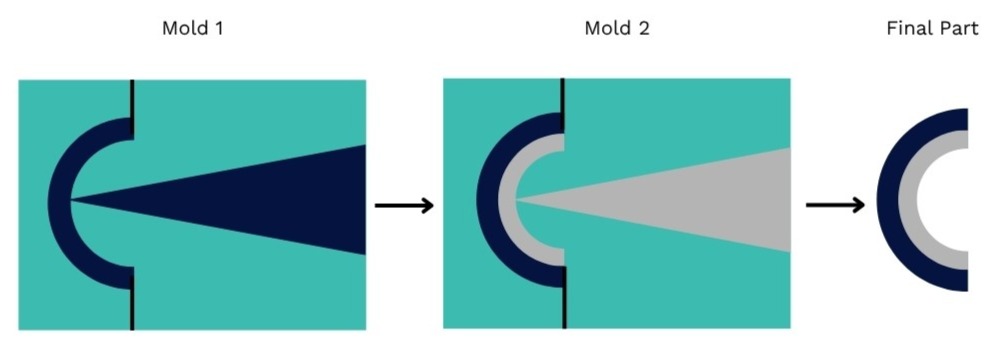

Insert molding: A pre-formed insert (polymer or metal) is placed in the mold before the second material is injected (Fig. 1).

Two-shot (2K) molding: Two polymers are injected sequentially within the same machine and mold system.

In both cases, the interface between the two materials determines the success of the process; chemically, thermally, and mechanically.

Figure 1. Overmolding with insert molding method

The Science Behind Strength and Softness

The key to overmolding lies in interfacial adhesion. When the second polymer is injected, its melt temperature must be high enough to promote molecular interdiffusion and entanglement with the substrate surface, but low enough to avoid substrate deformation.

Strength originates from the rigid substrate, typically an engineering thermoplastic such as PA6, PC, PBT, or ABS. These materials provide dimensional stability and load-bearing capability.

Softness or tactility is delivered by elastomeric overmolds such as TPE, TPU, or TPV, which impart flexibility, cushioning, and improved grip.

When designed properly, this combination forms a functional gradient across the part: stiffness where mechanical integrity is needed, and softness where user interaction occurs.

Critical Factors for Successful Overmolding

Material Compatibility: Chemical affinity between the substrate and overmold is crucial. For instance, TPU bonds well to PC and ABS, while TPE blends adhere better to PP-based substrates.

Temperature and Pressure Control: The melt temperature of the overmold must be high enough to promote interdiffusion but not so high that it causes distortion of the substrate.

Surface Preparation: Surface condition also plays a crucial role. Clean, dry, and thermally stable substrates promote optimal wetting of the overmold. In industrial practice, corona or plasma surface treatments are sometimes applied to improve interfacial energy and adhesion.

Mold Design: Mold design must accommodate differences in shrinkage, thermal expansion, and flow behavior between the two materials. Adequate venting prevents air traps, and balanced gating ensures uniform coverage of the interface. For precision parts, cooling control is essential to minimize warpage and residual stress. In case chemical bonding is limited, mechanical interlocking features; such as undercuts or textured surfaces; can enhance adhesion.

Shrinkage Management: Differences in shrinkage and cooling rates must be balanced to prevent delamination or warpage.

Industrial Applications

Overmolding is now a cornerstone technology across industries:

- Automotive: Knobs, handles, gaskets, vibration dampers.

- Medical devices: Ergonomic grips, seals, and housings that must combine sterilizability with comfort.

- Consumer electronics: Protective phone casings and soft-touch surfaces.

- Power tools and sporting goods: Enhanced grip and impact absorption.

By integrating materials directly during molding, manufacturers eliminate secondary assembly steps, reduce part count, and improve reliability.

Challenges and Design Optimization

The main challenges in overmolding are adhesion failures, warpage, and cycle-time optimization. Simulation tools can predict melt flow and cooling behavior, while laboratory-scale instruments; such as micro-injection molding machines; can also be used for material screening and interface testing.

Recent studies highlight how interface design, temperature, and chemistry affect bonding performance.

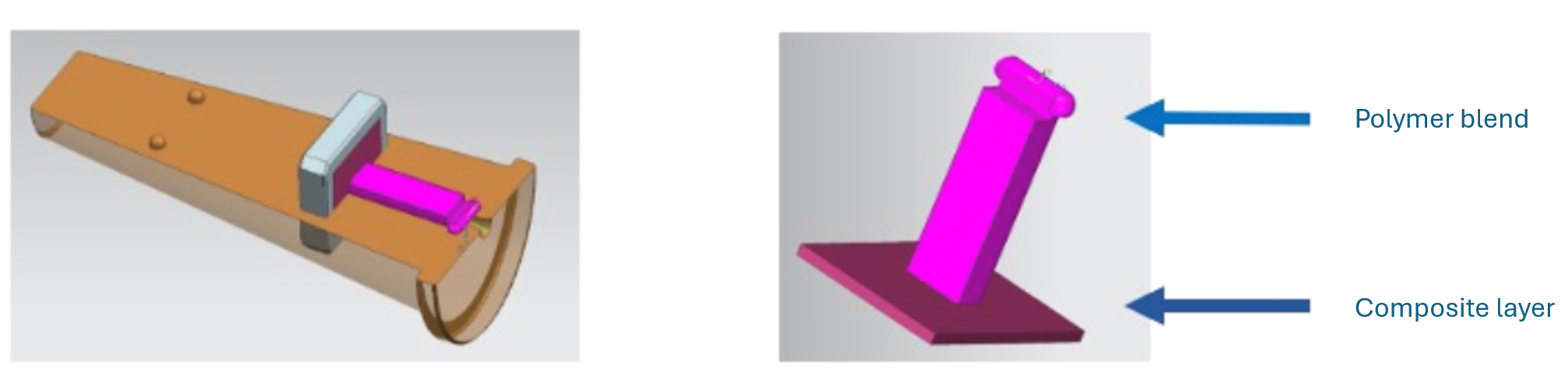

Akpınar et al. (2022) found that optimizing processing conditions significantly improved adhesion in injection overmolded composites (Fig. 2).

Karakaya et al. (2020) explored the overmolding parameters affecting adhesion between polyamide-6 (PA6) and continuous carbon or glass fiber/epoxy substrates to enable production of hybrid thermoset composites.

In a follow-up study, Karakaya et al. (2020) also showed that hot-melt adhesives can enhance wetting and bonding strength in hybrid overmolded structures.

Figure 2. Overmolding mold (for pure tension) and the sample [1]

All of these studies were conducted using Xplore micro-compounders and micro-injection molding systems, underscoring how these unique systems enable accessible, reproducible, and easy-to-manufacture sample geometries to test different materials and parameters effectively. With its micro-injection molding systems and custom mold design capability, Xplore enables researchers to:

- Rapidly prototype overmolded test specimens using only a few grams of material

- Study the effects of interface geometry, molding temperature, and polymer combinations

- Manufacture both standardized and tailor-made overmolding molds for laboratory and R&D use.

In short, Xplore bridges the gap between academic study and industrial practice, empowering scientists to accelerate their research on field of overmolding.

Conclusion

Overmolding exemplifies the evolution of polymer processing toward multifunctional design. By combining materials within a single molded structure, engineers can simultaneously achieve strength, comfort, and performance. Success relies on understanding material compatibility, thermal behavior, and interface physics; turning what was once a simple molding step into a powerful tool for product innovation.

References

- Akpınar S, Metin M, Koçoğlu H, Kodal M, Sezen M, Özkoç G, Altan MC. Improving bonding strength of injection overmolded composites. Polymer Engineering & Science. 2022; 62(10): 3206–3217. (Link)

- Karakaya N, Papila M, Özkoç G. Overmolded hybrid composites of polyamide-6 on continuous carbon and glass fiber/epoxy composites: an assessment of the interface. Composites Part A: Applied Science and Manufacturing. 2020; 131: 105771. (Link)

- Karakaya N, Papila M, Özkoç G. Effects of hot melt adhesives on the interfacial properties of overmolded hybrid structures of polyamide-6 on continuous carbon fiber/epoxy composites. Composites Part A: Applied Science and Manufacturing. 2020; 139: 106106. (Link)