Why Fiber Spreading Matters in High-Quality UD Tape Manufacturing?

Published: November 27, 2025 · Reading time: 3 minutes

Introduction

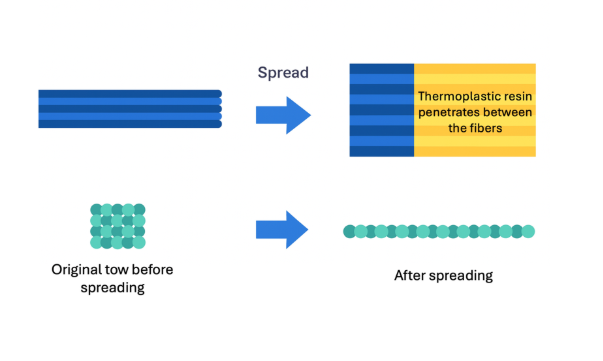

In thermoplastic composite processing, unidirectional (UD) tapes are essential building blocks for lightweight structural applications. Their performance depends not only on fiber and matrix selection, but critically on how effectively the fibers are spread before impregnation. Uniform spreading transforms a tow of thousands of filaments into a flat, open structure where each filament becomes accessible to the polymer melt (Fig. 1). This simple but decisive step drives the overall quality of the tape [1].

From Bundles to Performance: The Role of Spreading

Fiber tows naturally contain internal voids and micro-channels that restrict polymer penetration. When a tow remains compact, the polymer cannot easily reach the inner filaments, leading to:

- insufficient wet-out

- void formation

- heterogeneous fiber–matrix bonding

- reduced mechanical properties

Spreading resolves these challenges by increasing the tow’s surface area and reducing local thickness. A well-spread bundle allows the polymer to impregnate each filament uniformly, resulting in:

- consistent fiber volume fraction (FVF)

- improved load transfer

- clean, stable tape edges

- better consolidation during laminate processing

In essence: the quality of the spread defines the quality of the tape.

Figure 1. Fiber Tow Spreading Process

Impregnation and Darcy’s Law – Explained Simply

Polymer melt penetration into a fiber bundle follows Darchy’s law, which describes how fluids move through porous media. In simplified terms:

Flow rate ∝ Pressure × Permeability / viscosity

Practically:

- Higher permeability (achieved through spreading and polymer-fiber compatibility) supports deeper polymer flow.

- Lower viscosity (controlled by melt temperature) enhances wet-out.

- Sufficient differential pressure ensures the melt reaches the entire filament network (achieved through spreading).

Spreading and Darcy’s Law: How They Are Linked

When fibers are spread more uniformly, the internal structure of the tow becomes more open, increasing its permeability—one of the core parameters in Darcy’s law. This increased permeability means the polymer melt encounters less resistance as it flows through the filament network.

In contrast, a compact, poorly spread tow has low permeability, and the melt cannot easily reach the inner filaments, even under high pressure. This leads to partially impregnated cores, voids, and reduced mechanical performance [2].

Simply put:

Better spreading → higher permeability → more efficient impregnation → higher-quality UD tape.

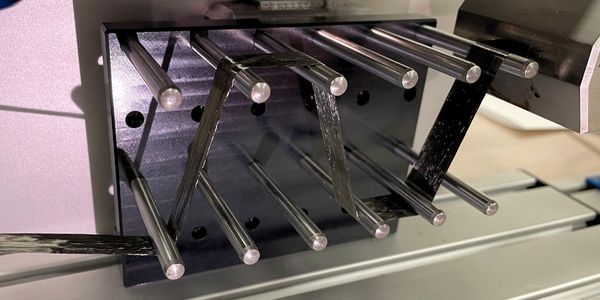

Spreading on a Round Surface

In many UD-tape production systems, fibers are not only spread on flat bars but also across round or cylindrical surfaces, such as spreading rollers or tension rollers. When the tow passes over a curved surface, the bending induces controlled filament separation: outer filaments travel a slightly longer path than inner ones, creating natural micro-slippage within the bundle. This curvature-driven separation promotes more uniform filament distribution and increases the tow’s permeability, directly supporting Darcy-governed melt flow. Spreading on round surfaces is particularly effective for carbon and glass fibers, where controlled tension and curvature produce significant improvements in tow opening with minimal mechanical energy input.

Figure 2. Xplore’s Spreading Unit

Investigating Spreading Phenomena with the Xplore Micro UD-Tape Line

Xplore’s micro-UD tape line offers researchers a unique platform to investigate spreading behaviour with exceptional control and precision. Users can manipulate spreader-bar arrangements, adjust surface roughness, and fine-tune fiber tension to study how each variable influences tow opening, permeability, and final tape quality. This modular design enables detailed visualisation and experimentation with carbon, glass, natural, and recycled fibers under realistic processing conditions. It also provides an excellent environment for validating spreading models, understanding impregnation governed by Darcy’s law, and developing optimized processing strategies before moving to industrial-scale tape production.

Figure 3. Xplore Micro UD-Tape Line

Conclusion

Fiber spreading is not just a preliminary step; it is the foundation of high-performance UD tape manufacturing. By opening the bundle and increasing permeability, spreading allows the polymer melt to access every filament, ensuring strong, uniform, and reliable composite tapes. With Xplore’s micro-UD tape line, these spreading mechanisms can be studied and optimized at a level of detail that larger systems cannot offer.

References

- Moradi A, Sun C, Guan Z, Rastegarzadeh S. Technology for lateral spreading of fibre bundles for applications in manufacturing thermoplastic composites. Composites Part A: Applied Science & Manufacturing. 2023. (LINK)

- Mischorr E, Schaible P, Würfel V, Keil J, Gelencsér A, Schabel S, Fleischer J, Gude M. Advanced manufacturing of thermoplastic tape preforms: braiding simulation, curved preforming, and consolidation via rotational and bladder-assisted molding. Advanced Manufacturing: Polymer & Composites Science. 2025. (LINK)