How Does Fiber Spinning Help Benchmark Sustainable & Bio-Based Polymers?

Published: December 11, 2025 · Reading time: 5 minutes

Introduction

In polymer engineering, spinning is one of the most fundamental material-to-fiber transformation processes. Whether performed as monofilament (one single strand) or multifilament (dozens to hundreds of continuous strands), spinning enables the conversion of a molten or dissolved polymer into a long, uniform filament with well-defined mechanical and thermal properties. By carefully controlling melt flow, cooling, and drawing, the process produces fibers with tailored strength, flexibility, and surface characteristics, properties essential for textiles, medical sutures, filtration media, or technical yarns.

What makes spinning particularly relevant today is the material shift underway. Researchers are increasingly working with bio-based sustainable polymers whose behavior differs markedly from conventional fossil-based grades. Many of these sustainable polymers have lower melt strength, distinct crystallization kinetics, or variable molar-mass distributions. Spinning, therefore, becomes more than a shaping method; it becomes an analytical tool to understand how chemistry, rheology, and processing interact.

Understanding the Spinning Process

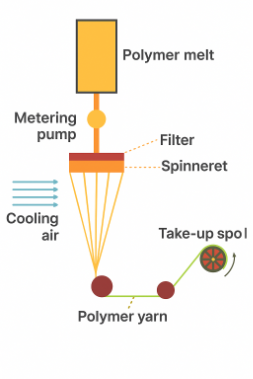

In melt spinning, polymer granules or pre-aligned blends are melted, homogenized, and pressed through a spinneret containing a single or multiple capillary openings. The emerging filaments are then quenched by controlled air or water cooling, stabilizing their geometry before they are drawn at defined take-up speeds (Fig. 1). This drawing step aligns polymer chains, increases crystallinity, and ultimately defines tensile strength and elongation.

Figure 1. Schematic process flow of fiber-spinning

Because spinning magnifies the molecular features of a polymer, its viscosity, thermal stability, and intermolecular interactions, the process is highly sensitive to formulation changes. Even small modifications in chain architecture, copolymer ratio, or crystallinity level can become immediately visible through spinnability, filament surface appearance, or draw-down behaviour.

Emerging Topics in Spinning Research

Across academic and industrial laboratories, several themes are gaining momentum:

- Ultrafine and micro-diameter filaments for lightweight filtration and biomedical devices

- Bio-based and hybrid copolymers tailored for reduced environmental impact

- Recycled-content filaments where viscosity recovery, melt purity, and chain architecture determine spinnability

- Functional fibers incorporating smart, conductive, or antimicrobial components

- Structure-property mapping, where spinning reveals polymer behavior that bulk tests cannot predict

As sustainability targets tighten and new chemistries emerge, spinning offers a direct route to understand which formulations are viable for scale-up.

Why Spinning Matters for Sustainable Polymers

Recent scientific work demonstrates how spinning provides critical insights into the processability and performance potential of new bio-based polymers.

One example is the development of bio-based PA6.19/6.6 copolyamides, in which researchers explored how long-chain diacid monomers can be converted into high-strength monofilaments [1]. By conducting melt-spinning trials, they showed that the copolymers not only reached industrial-grade draw-down ratios but also delivered tensile strength comparable to fossil-based PA6, highlighting spinning as a decisive step in validating new sustainable polyamide chemistries.

A second recent study investigated elastomeric lactic-acid-based copolymers for biomedical applications [2]. Here, monofilament spinning was used to evaluate the effect of a bio-derived plasticizer on filament integrity, elasticity, and surface morphology. The work demonstrated how even small compositional changes can be monitored through filament formation, enabling a rapid assessment of how bioresorbable materials might behave as sutures.

These studies underline a broader trend: as the polymer landscape becomes more diverse, spinning is increasingly used as a diagnostic technique to understand how sustainable materials behave under realistic processing conditions for certain end-use applications.

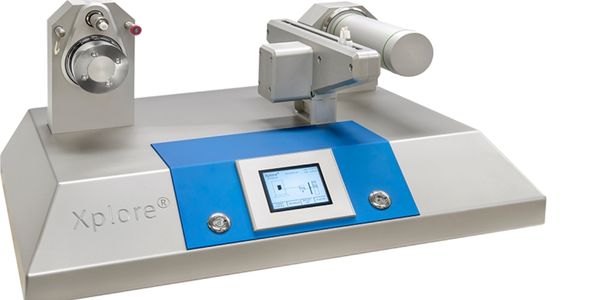

Rapid Screening With Xplore Micro-Processing Tools

Laboratory-scale spinning becomes especially valuable when only limited material quantities are available, a common situation in early-stage polymer development. Xplore’s micro-compounders, micro-injection units, and benchtop fiber-spinning systems are designed for this purpose (Fig. 2), allowing researchers to:

- process 15-40 g batches,

- precisely control temperature profiles,

- evaluate spinnability at different take-up speeds,

- and correlate polymer composition with filament quality.

By combining customized compounding, filament formation, and mechanical testing on a compact scale, researchers can rapidly determine whether a polymer formulation is suitable for further development.

(a)

(b)

Figure 2. Xplore Micro Fiber Spinning Line (a) General setup (b) Take-up roll

Conclusion

Spinning remains one of the most insightful processing techniques in polymer research. For emerging sustainable materials, bio-based, recycled, or chemically modified, melt spinning provides immediate feedback on stability, orientation, and mechanical potential. As recent research demonstrates, combining innovative polymer chemistry with small-scale spinning tools offers a powerful route to accelerate the development of next-generation fibers.

References:

- Rist M, Löcken H, Ortega M, Greiner A. Toughening of bio-based PA 6.19 by copolymerization with PA 6.6 – synthesis and production of melt-spun monofilaments and knitted fabrics. Macromolecular Rapid Communications. 2023; 44: 2300256. (Link)

- Gallos A, Reffuveille F, Guillaume C, Varin-Simon J, Gangloff S, Allais F, Velard F. Tuning thermo-mechanical properties of elastomeric lactic acid-based copolymers for biomedical applications. Green Chemistry Letters and Reviews. 2025; 18(1). (Link)