Developing Medical (Micro)-Tubes for Biomedical Applications: Rapid Prototyping with Micro-Processing

Published: January 15, 2026 · Reading time: 2 minutes

Introduction

Medical tubing is a foundational component in biomedical devices such as catheters, drainage systems, infusion lines, and ophthalmic implants. Although seemingly simple, medical tubing is a highly engineered product whose performance depends on material formulation, processing history, dimensional precision, and surface quality.

Thin-walled micro-tubes with sub-millimeter dimensions are increasingly used in applications such as wound drainage and glaucoma treatment. These devices must combine biocompatibility, flexibility, dimensional stability, and reliable long-term performance.

Micro-compounding: Designing the Tubing Material

Micro-compounding enables formulation development using gram-scale material quantities under realistic melt-processing conditions. This allows rapid screening of biomedical-grade polymers, blends, and additives before scale-up.

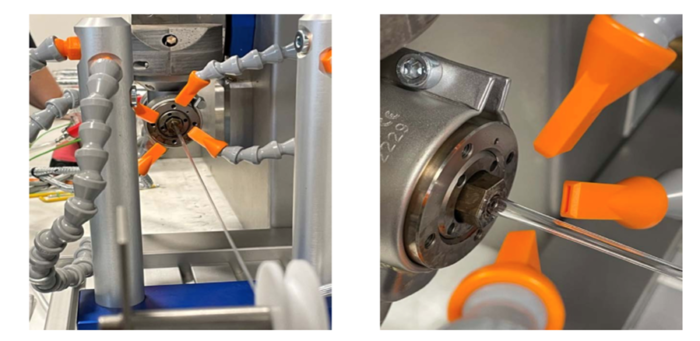

Xplore micro-tube extrusion technology enables continuous extrusion of thin-walled tubes using a micro-tube die coupled to an MC 15 HT or MC 40 (Fig. 1). Pressurized lumen air prevents tube collapse, enabling precise control of tube geometry.

Figure 1: Micro-Tube Die Attached to MC 15 HT

Processing–Structure Relationship

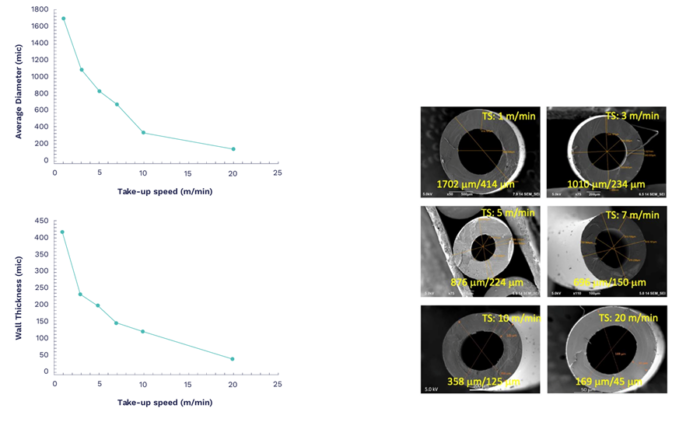

By varying the take-up speed while keeping melt temperature and feed rate constant, tube diameter and wall thickness can be precisely controlled. Outer diameters as low as 170 µm and wall thicknesses down to 45 µm have been demonstrated using a thermoplastic medical grade polyurethane (Fig. 2).

Figure 2: Effect of Take-Up Speed on Tube Dimensions and LM images showing the coaxiality & micro-tube dimensions

Why Micro-Compounding and Micro-Tube Extrusion Belong Together

The integration of micro-compounding and micro-tube extrusion enables a seamless workflow from material formulation to application-ready tubing prototypes using minimal material. Micro-compounding combined with micro-tube extrusion provides a powerful platform for rapid prototyping of medical tubing. This approach reduces development time, minimizes material waste, and de-risks scale-up for next-generation biomedical products.

This article summarizes key aspects of the application. For a deeper technical analysis and detailed results, we invite you to read the full application note here: https://bit.ly/4sHeLcD