An Innovative accessoiry for an Xplore MC 15 HT; a tow impregnation die

An Innovative accessory for an Xplore MC 15 HT; a tow impregnation die.

Xplore is in the commercialisation phase of an innovative tow impregnation die (TID); an accessory for our MC 15 HT and MC 40 compounder.

The newly designed TID can be easily mounted at the die exit of our larger compounders. The TID is accurately temperature-controlled via electrical heating element. Hence, it enables the user to have better control of the flow properties of the polymeric material inside the die.

First initial prototype testing reveals that this TID enables you to coat multifilament fibres with a polymeric material. The ultimate challenge with coating multifilament fibre bundles is that ideally, each individual filament should be wetted with a polymeric material to prevent inconsistencies in the material properties, such as premature failure, due to stress localisation, of the end product. The Xplore TID first spreads the fibre bundle in the die over the transverse-axis using specially designed spreader pins, allowing the molten polymeric material to get in between each fibre, shortly said: basically, wetting each fibre individually.

Applications like UD-tape production with glass, natural or carbon fibres or continuous fibre filament production for 3D-printing of composites will benefit from this technology. Now, each individual fibre can be wetted (no voids or agglomerated “un-wetted” fibres present); complex shape and angles can be 3D printed without decreasing the structural integrity of a nascent 3D printed object.

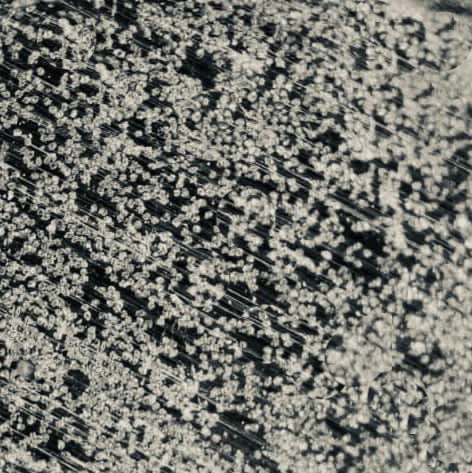

See in Figure 1, showing the proof of principle where a multi-filament fibre was coated with a polyester resin.

Now, investigating the compatibility of certain (natural) fibre bundle materials and its polymers interaction can now be studied more efficiently than ever.

Xplore will inform you, on this platform, regularly about the progress of commercialisation of this Tow Impregnation Die.