High-quality recyclates for sustainable products

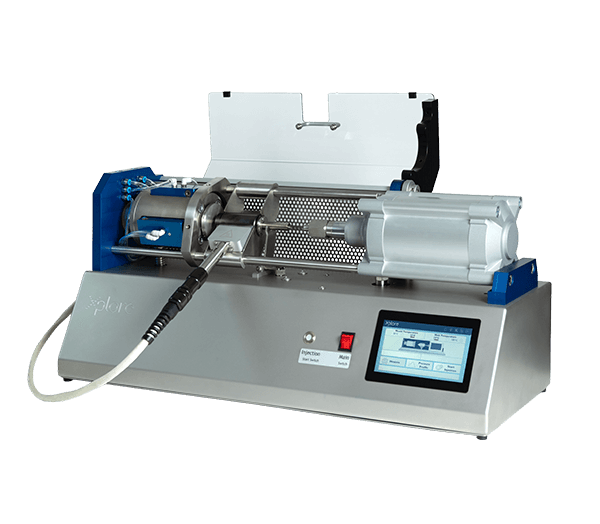

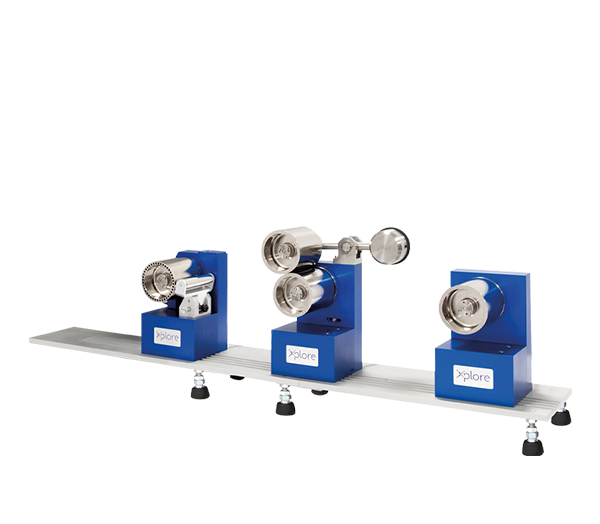

Micro-compounders are essential for developing recycled and sustainable polymeric materials, enabling efficient formulation, rapid screening, and precise processing with minimal material use. They help optimize polymer properties, enhance recyclate quality, and reduce costs while ensuring reproducibility and scalability. Xplore’s micro-compounders support mechanical recycling R&D, transforming plastic waste into high-quality recyclates with additives or fillers. They enable chemical modifications, real-time viscosity monitoring, and precise sample shaping using post-die tools. With volumetric dosing for stable throughput, Xplore accelerates plastic-to-plastic loops, driving circular economy solutions and helping researchers develop eco-friendly polymers quickly and effectively.

Support

Xplore provides exceptional support for the circularity & sustainability market, offering comprehensive resources like whitepapers, technical documents, FAQs, and expert guidance to optimize machine performance and streamline R&D processes.

Technical notes Specification sheets FAQ ContactThe small capacity of Xplore’s equipment helped us optimize our formulations with just a few grams of PHA, allowing us to do a wider variety of trials with less time, less effort and fewer materials.

Reza Beigi

Product Lead

Uulu

Be inspired

Optimising PHA at Gram Scale with Xplore

How Uluu used lab-scale PHA processing with Xplore systems to optimize formulations using only a few grams of material.

Read more

How Continuous Feeders Improve Accuracy in Micro-Compounding?

Continuous micro-compounding feeding enables stable and reproducible polymer processing through precise pellet and powder dosing at lab scale.

Read more

Developing Medical (Micro)-Tubes for Biomedical Applications: Rapid Prototyping with Micro-Processing

How micro-compounding and micro-tube extrusion support rapid prototyping of precision medical tubing.

Read more