Revolutionizing polymer R&D with efficiency

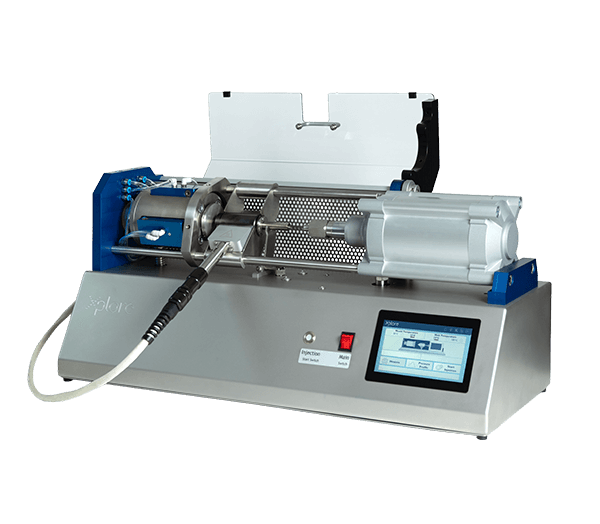

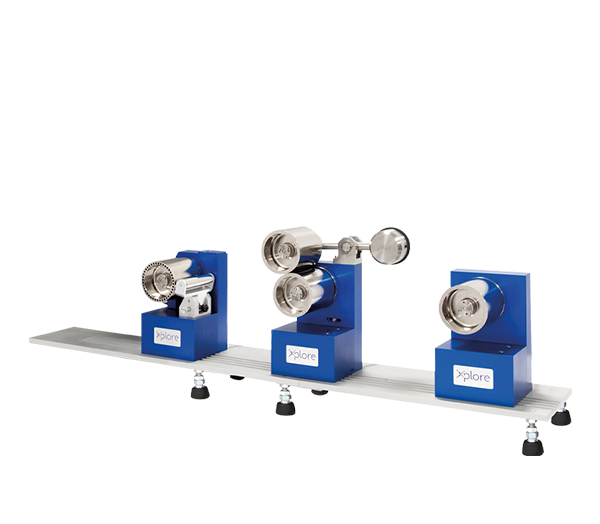

Xplore’s high-quality conical twin-screw micro-compounders accelerate formulation development, screening, and feasibility studies, reducing time and costs. Despite their compact design, they enable process scaling comparable to continuous parallel twin-screw extruders. These robust, long-lasting compounders offer superior mixing, reproducibility, and efficiency. Xplore also provides micro post-die shaping instruments like injection molders and fiber lines, further streamlining polymer R&D. With over 30 years of expertise, Xplore helps bring innovative polymer products to market faster. Xplore has also developed dedicated micro post die shaping instruments, such as our injection moulders, cast film lines, and fiber line, further simplifies and accelerates your polymer materials testing activities. Hence speeding up your product to market time.

Let's explore our other solutions

View all products

Support

Xplore provides exceptional support for the polymer market, offering comprehensive resources like whitepapers, technical documents, FAQs, and expert guidance to optimize machine performance and streamline R&D processes.

Technical notes Specification sheets FAQ ContactBe inspired

Spiral mold to compare the flow characteristics of polymers

When using our spiral mould you will be able to quickly compare flow properties of highly filled systems and get an idea of the sample viscosity.

Read more

Enabling Shape Memory Biomedical Materials with Micro-Compounding

Explore shape memory polymers for biomedical devices, from PLA/TPU blends to compatibilization and micro-processing for reliable performance.

Read more

Optimising PHA at Gram Scale with Xplore

How Uluu used lab-scale PHA processing with Xplore systems to optimize formulations using only a few grams of material.

Read more