Advancing Rubber R&D: Faster, Cleaner, and More Efficient Compounding

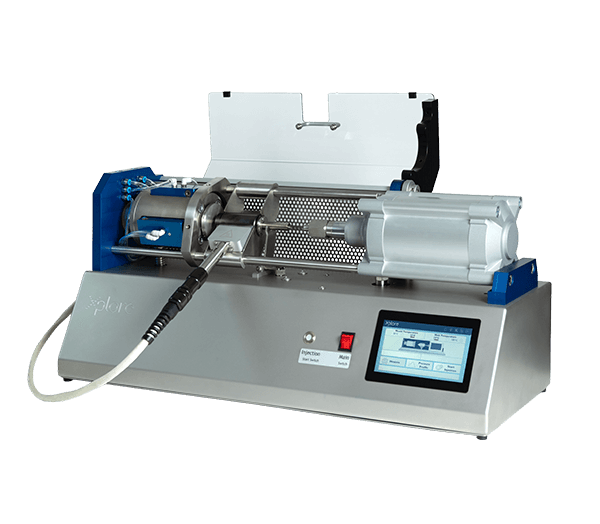

Rubbers and elastomers are essential across industries, requiring efficient formulation technologies for innovation and performance. Traditional Banbury-type internal mixers are labor-intensive, slow, difficult to clean, and require large material volumes (300–400 ml), making them costly and inefficient—especially for expensive additives. They also demand significant lab space due to carbon black (CB) dusting. Xplore’s MC 15 HT and MC 40 micro-compounders offer a faster, cleaner, and more efficient alternative. With 40 Nm of torque and fully intermeshing screws, they ensure uniform mixing, overcoming the inconsistencies of tangential screw designs. These micro-compounders process 15–40 ml of rubber in just 5 minutes, compared to the 30-minute traditional process, reducing material costs, chemical exposure, and turnaround time. Ideal for feasibility studies, formulation screening, and technical marketing, Xplore’s solutions streamline rubber R&D with precision and efficiency.

Support

Xplore provides exceptional support for the rubber and elastomer market, offering comprehensive resources like whitepapers, technical documents, FAQs, and expert guidance to optimize machine performance and streamline R&D processes.

Technical notes Specification sheets FAQ ContactBe inspired

How Benchtop Tools Transform LFT Research from Complex to Accessible?

Learn how long-fiber thermoplastics improve strength and impact resistance, and how micro-compounding enables fast LFT research.

Read more

Optimising PHA at Gram Scale with Xplore

How Uluu used lab-scale PHA processing with Xplore systems to optimize formulations using only a few grams of material.

Read more

How Continuous Feeders Improve Accuracy in Micro-Compounding?

Continuous micro-compounding feeding enables stable and reproducible polymer processing through precise pellet and powder dosing at lab scale.

Read more