Stay up to date

On this page, you’ll find all the latest Xplore news, from cutting-edge technologies to updates about our team.

Stay tuned for insights and developments from Xplore!

Blog

BlogOptimising PHA at Gram Scale with Xplore

How Uluu used lab-scale PHA processing with Xplore systems to optimize formulations using only a few grams of material.

Blog

BlogHow Continuous Feeders Improve Accuracy in Micro-Compounding?

Continuous micro-compounding feeding enables stable and reproducible polymer processing through precise pellet and powder dosing at lab scale.

Blog

BlogDeveloping Medical (Micro)-Tubes for Biomedical Applications: Rapid Prototyping with Micro-Processing

How micro-compounding and micro-tube extrusion support rapid prototyping of precision medical tubing.

Blog

BlogEnabling Shape Memory Biomedical Materials with Micro-Compounding

Explore shape memory polymers for biomedical devices, from PLA/TPU blends to compatibilization and micro-processing for reliable performance.

Blog

BlogHow Does Fiber Spinning Help Benchmark Sustainable & Bio-Based Polymers?

Discover how melt spinning reveals the processing behavior of sustainable polymers and how Xplore micro-systems enable small-scale fiber research.

Blog

BlogWhy Fiber Spreading Matters in High-Quality UD Tape Manufacturing?

Learn how fiber spreading improves polymer impregnation and UD-tape quality, and how Xplore’s micro UD-tape line enables precise process research.

Blog

BlogHow Overmolding & Insert molding Merges Strength and Softness into a Single Functional Part?

Discover how overmolding combines strength and softness in one molded part, and how Xplore systems enable precise research on polymer interfaces.

Blog

BlogWhy Are Nanocomposites Becoming So Important in Polymer Research?

Discover how polymer nanocomposites enhance material performance and how Xplore micro-compounders enable precise, small-scale research and processing.

Blog

BlogHow to Control Residence Time in Conventional Extrusion?

Why residence time matters in extrusion and how Xplore batch micro-compounding enables precise control for consistent polymer properties.

Blog

BlogHow to Prevent Shrinkage and Sink Marks in Injection Molding

Learn why shrinkage and sink marks form in injection molding and how the Xplore IM12 helps study and prevent these defects.

Blog

BlogWhy Do Polymers Degrade During Extrusion and How Can You Limit It?

Why polymers degrade during extrusion, and how antioxidants and Xplore micro-compounders help prevent it.

Blog

BlogWhat Really Happens When You Mix Hard Fillers into Plastics?

Learn how to process high-filler thermoplastics efficiently. Explore wear control, dispersion, and micro-compounding solutions for advanced polymer R&D.

Blog

BlogWhy Compounding Is Key to Recycling Post-Consumer Plastics

How extrusion turns mixed post-consumer plastics into consistent, high-performance compounds ready for real-world applications.

Blog

BlogHow are Flame-Retardant Thermoplastics evolving, and what role do Micro-Compounders play?

Discover new flame-retardant thermoplastics, from halogen-free and bio-based additives to lab tools that speed safer material design.

Blog

Blog3D Printing and the Future of Filaments

Explore the evolution of 3D printing filaments and how lab-scale tools speed up new material development.

Blog

BlogUnderstanding Cast and Blown Film Technologies in Polymeric Film Processing

Explore polymer film processing, cast vs blown films, and how benchtop systems help study orientation, properties, and R&D at small scale.

Blog

BlogMelt spinning of fibers

Learn how polymer fibers are developed via melt spinning and drawing using lab-scale Xplore systems.

Blog

BlogLab-Scale Polymer Processing: The Power of Batch Micro-Compounding

Batch micro-compounding allows efficient lab-scale polymer testing. Researchers can optimize formulations and get reliable results with minimal material.

Blog

BlogEffect of barrel gap on the dispersion quality of carbon black in rubber compounds

What does it mean when you change the barrel screw gap in relation to distribution and dispersion of particles in a rubber matrix.

Blog

BlogIn-mold crosslinking of rubber compounds

The Xplore MC 15 HT high torque laboratory micro-compounder and IM 12 combo also offers high-viscous rubber processing capabilities.

Blog

BlogMaintenance services

Xplore does offer maintenance services for your precious Xplore equipment, prolonging the machine’s lifetime and ensuring you are compliant.

Blog

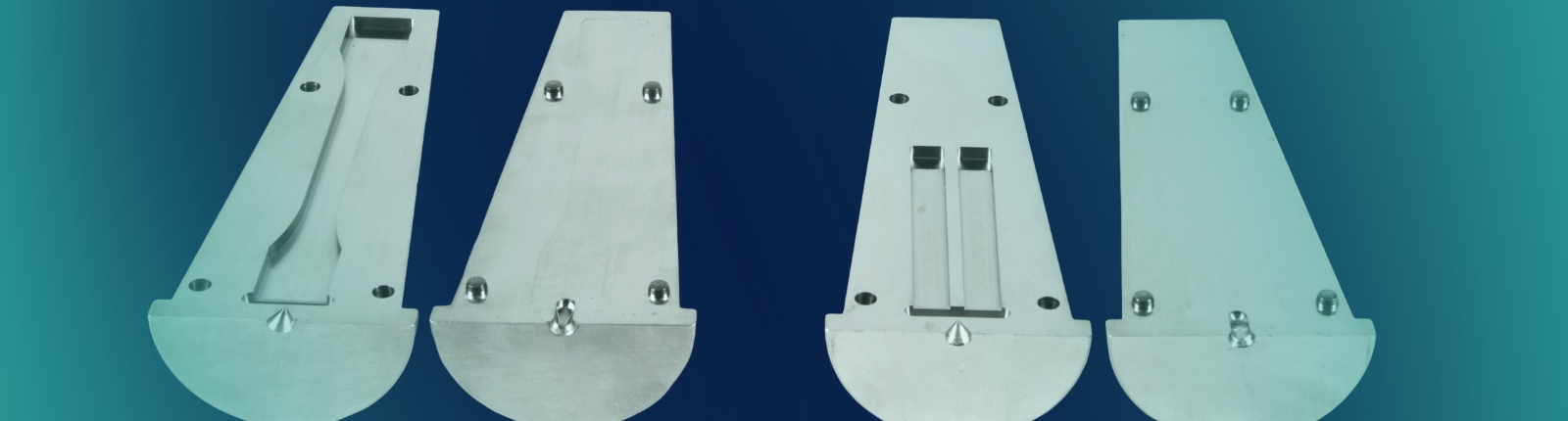

BlogSpiral mold to compare the flow characteristics of polymers

When using our spiral mould you will be able to quickly compare flow properties of highly filled systems and get an idea of the sample viscosity.

Blog

BlogXplore’s MC 40 micro-compounder in continuous compounding mode

Xplore’s MC 40 micro-compounder is used in continuous compounding mode. Is it any good?

Blog

BlogImproving the pellet quality with the optimization of process parameters in Xplore Pro-Pelletizer

Xplore MC 15 HT; an excellent mixer for rubber R&D. Process small amounts of rubber into a homogeneous test sample in less than 5 minutes.

Blog

BlogPro Pelletizer

The R&D size Xplore Pro Pelletizer post-die granulation unit is specially designed to cut also highly filled abrasive engineering plastics into pellets (granules).

Blog

BlogXplore Instruments and your circular materials and recyclates R&D needs, how we could help.

Xplore MC 15 HT, a perfect tool to screen improve your recyclates.

Blog

BlogAn Innovative accessoiry for an Xplore MC 15 HT; a tow impregnation die

The newly designed TID can be easily mounted at the die exit of our larger compounders. The TID is accurately temperature-controlled via electrical heating elements.