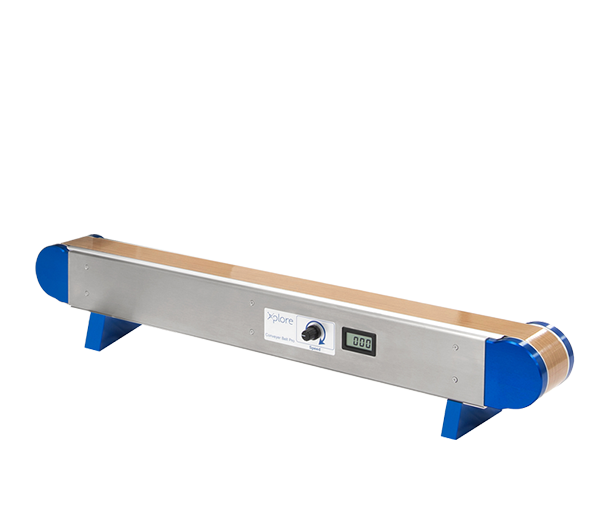

CB Pro (Conveyor Belt Pro)

Xplore Conveyor Belt Pro (CB Pro) unit is specifically designed to guide polymer strands directly from a small extruder or compounder die, offering seamless integration with the MC 5, MC 15 HT, and MC 40 models. With an adjustable belt speed, it allows precise customization for various applications. Unlike conventional extrusion into a water bath, the polymer strand is deposited onto a non-stick PTFE conveyor belt, which carefully and consistently draws the fragile, nascent strands in a controlled manner. This prevents breaks or cracks while ensuring the polymer cools in a predetermined shape, ready for further analysis or direct feeding into a small pelletizer. By maintaining the integrity of the strand during cooling, the CB Pro enhances process stability and efficiency, making it an essential tool for precise polymer handling in research and development settings.

Key Features

The Xplore Conveyor Belt Pro (CB Pro) unit offers a large operating window with prolonged draw rates as low as 1 m/min, allowing precise control over polymer strand processing. Its gentle, straight-line cooling mechanism prevents strand breaks, ensuring a smooth transition to subsequent analysis or pelletizing steps. Additionally, the CB Pro can be retrofitted into existing extrusion lines, making it a versatile and efficient solution for polymer processing in research and development applications.