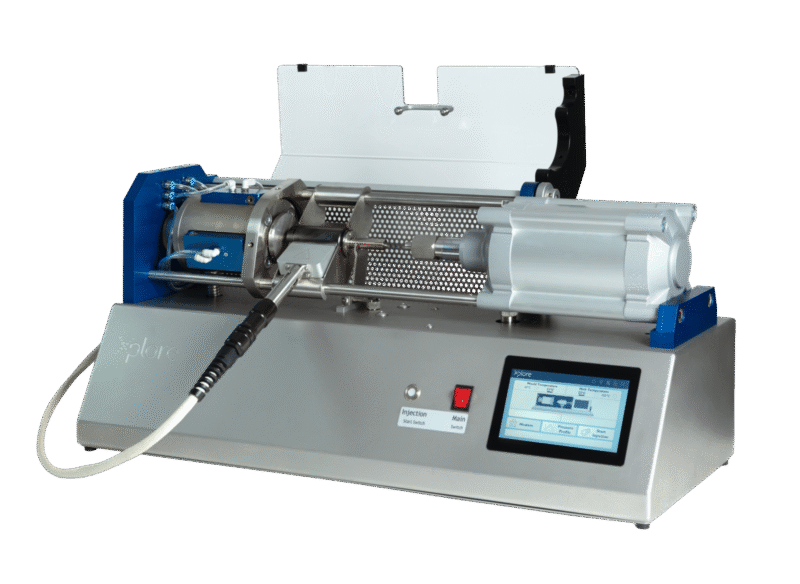

IM 12 Pro Injection Moulder

The Xplore IM 12 Pro Injection Moulder is a compact, high-precision system designed for efficient R&D screening, easily fitting on a laboratory bench or inside a fume hood. With a 12 ml shot volume, it integrates seamlessly with Xplore twin-screw micro-compounders or operates as a standalone unit for formulations that do not require mixing. The IM 12 Pro enables fast, reliable, and cost-efficient testing of new or high-value materials using minimal sample volumes. Its advanced temperature-controlled mould housing now features improved heating performance for quicker temperature ramp-up and optional active cooling down to sub-ambient levels. This extended thermal range allows precise control of the mould temperature profile and, consequently, of the sample’s morphology and crystallization behavior. A securely locked conical mould prevents flashing and ensures clean, repeatable results. A compressed-air-driven plunger delivers accurate injection, while adjustable holding pressure and timing minimize shrinkage. The injection chamber can be refilled directly from an Xplore micro-compounder or manually with powders or granules, enabling one or more injection cycles per batch depending on the mould volume. Multi-cavity mould configurations allow multiple test specimens per cycle. Standard mould options include certified dog-bone tensile bars, Izod bars, and pharmaceutical tablet shapes, with custom moulds available upon request. Compact, versatile, and accurate, the Xplore IM 12 Pro combines precision, flexibility, and advanced thermal control, an ideal tool for rapid material screening and formulation development in research environments.

Key Features

The Xplore IM 12 Pro Injection Moulder offers a maximum shot volume of 12 ml and accommodates moulds with up to 12 ml cavity capacity. Its advanced heating and cooling system enables mould temperatures from ambient up to 150 °C in under 10 minutes, with water-assisted cooling bringing the temperature back down just as fast. Optional liquid-cooled plates, compatible with standard lab chillers, allow mould temperatures as low as sub-ambient levels, while the transfer unit reaches 150 °C in under 5 minutes and can be heated up to 450 °C. The system supports programmable pressure profiles between 1–16 bar over time, delivering an injection force of up to 18 kN at 16 bar. With a maximum mould temperature of 300 °C, integrated USB data acquisition, and compact dimensions (84 × 33 × 35 cm; 50 kg), the IM 12 Pro combines high performance, fast thermal response, and bench-top convenience. Power supply: 208–240 V AC (other voltages on request).