How Benchtop Tools Transform LFT Research from Complex to Accessible?

Published: February 20, 2026 · Reading time: 5 minutes

Introduction

Reinforced thermoplastics combine a polymer matrix with stiff, lightweight fibers, enabling high specific strength, corrosion resistance, impact resistance, and processability. In particular, long-fiber thermoplastics (LFT) research has gained increasing attention as thermoplastic composites continue to grow in strategic importance in automotive, aerospace, and defense applications, where weight reduction, design flexibility, and high mechanical performance must be achieved in recyclable systems.

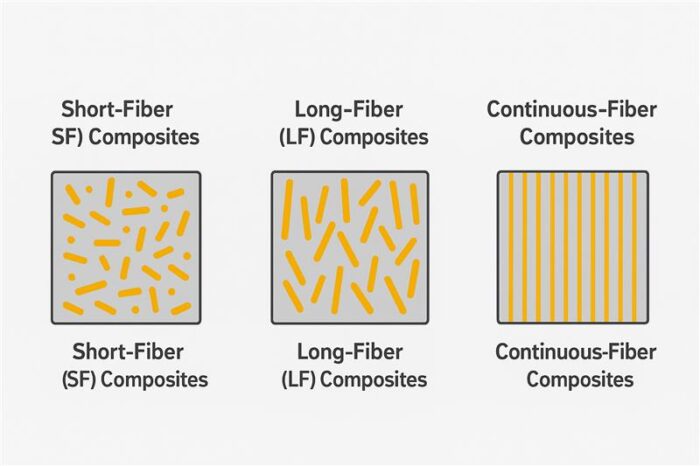

Depending on reinforcement length, thermoplastic composites are typically classified as (Fig. 1):

- Short-fiber (SF) composites (< 1 mm)

- Long-fiber (LF) composites (1-25 mm)

- Continuous-fiber composites (average fiber length equal to the part dimension)

Figure 1. Thermoplastic composites classification according to reinforcement length

In SF and LF systems, fibers are discontinuous and become randomly or preferentially oriented during processing.

Long Fiber Thermoplastics (LFTs) strike an attractive balance: they maintain higher aspect ratios in the final part, providing substantially improved strength, stiffness, impact performance, wear resistance, and thermal stability. However, retaining fiber length is challenging due to fiber breakage, wet-out limitations, and melt-flow constraints.

Industrial LFT production relies on pultrusion combined with hot-melt impregnation, where continuous tows are coated with molten polymer, cooled, and pelletized. Materials frequently used include PP (~65% of the global market), PA6, PA66, and high-temperature polymers such as PPS and PEEK. Reinforcements range from glass and carbon fibers to aramid and natural fibers.

Some Key Examples from LFT Research Studies

Research in LFTs targets a broad set of structure-property relationships: fiber type and surface chemistry, fiber dispersion and orientation, volume fraction, final fiber length, melt viscosity, impregnation time, compatibilizers, co-fillers, hybrid reinforcements, and interfacial adhesion. Understanding these variables remains essential for predicting crash behavior, improving durability, and designing lighter and safer structural components.

Below, there are several significant example studies which deepen the understanding of how LFTs behave and why fiber length, hybridization, and processing routes matter.

Lee et al. [1] examined hybrid long-fiber PP composites combining carbon and glass fibers. They observed a clear hybrid effect in tensile modulus between 6–10 vol% carbon fiber, and documented electrical percolation thresholds near 8-12 vol% LCF. The study highlights how hybrid architectures allow simultaneous tuning of stiffness, conductivity, and cost, an increasingly attractive pathway in automotive semi-structural parts.

Cui et al. [2] showed that long-glass-fiber PP exhibits strong strain-rate sensitivity: strength and fracture strain nearly double from 0.001-400 s⁻¹, while modulus stays constant. Failure shifts from fiber pull-out to fiber breakage due to improved interfacial bonding and local adiabatic heating, enhancing energy absorption under high-speed loading.

Whitfield et al. [3] analyzed thermal and molecular changes along a full D-LFT line for PA6 composites. They found decreasing viscosity number (molecular weight) across the process, and significant changes in crystallization kinetics after each extrusion stage. Their work shows that polymer degradation, moisture content, and fiber-induced nucleation influence final morphology and thus mechanical performance.

How Micro-Compounding Enables Reliable and Fast LFT Research

Traditional LFT research requires extensive infrastructure, high volumes of material, and costly production trials. Micro-compounding transforms this workflow by enabling:

- Controlled shear levels that preserve fiber length

- Accurate screening of fiber types, compatibilizers, and hybrid reinforcements

- Rapid formulation cycles using only a few grams of material

- Direct molding of ISO-compliant specimens via IM12

- Reproducible data that reliably predicts industrial-scale behavior

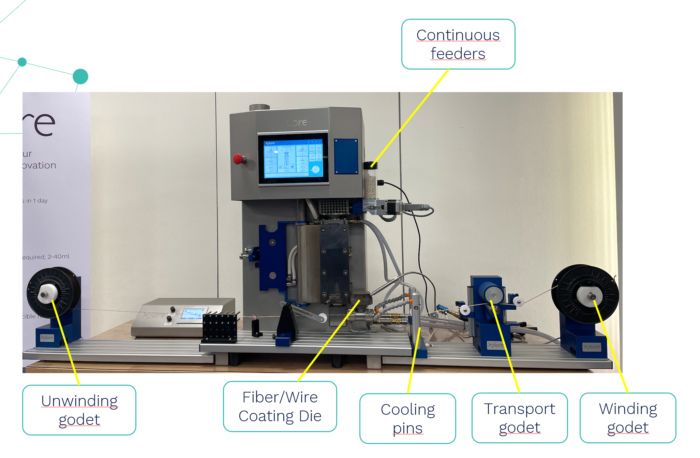

Recent work at Xplore demonstrates how laboratory-scale coating and compounding line (Fig. 2) enables high-quality LFT formulation with drastically reduced material consumption and time.

Figure 2. Xplore Fiber/Wire Coating Line

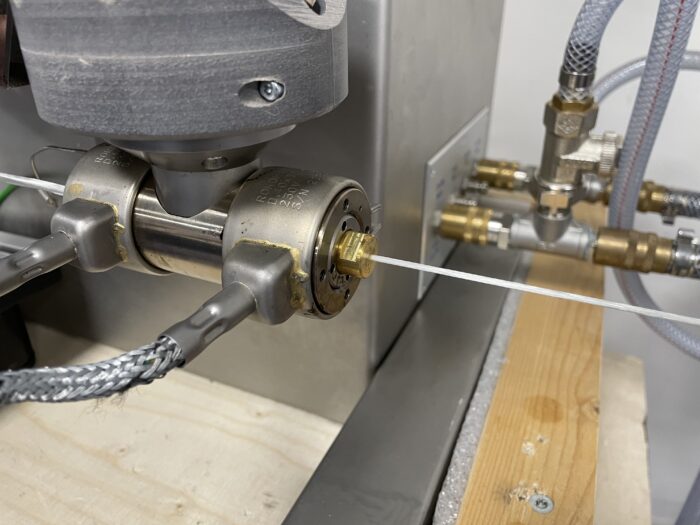

Continuous glass fiber rovings were coated with polypropylene using an Xplore MC40 micro-compounder using the fiber coating die (Fig. 3), processed into strands, pelletized into 10 mm LFT pellets, and subsequently melt-compounded in direct-compounding mode using the MC15HT. ISO 527 Type 1A specimens were molded using the IM12 micro-injection molder.

Figure 3. Fiber/Wire Coating Die

Rheological analysis revealed that LFT samples displayed the highest viscosity and strongest shear-thinning behavior, reflecting fiber–fiber interactions and efficient load transfer within the melt. Mechanical tests showed that LFT specimens outperformed short-glass-fiber PP by approximately 13% in tensile strength and 32% in tensile modulus, confirming that preserving fiber length is critical to composite performance.

This study illustrates that laboratory-scale tools, when designed for controlled shear, direct feeding, and minimal residence time, can reproduce representative LFT behavior with only grams of material.

Conclusion

Long-fiber thermoplastics provide a valuable balance between short-fiber compounds and continuous-fiber composites. Their ability to retain longer, load-bearing fibers delivers significant gains in stiffness, toughness, and impact resistance, while remaining compatible with fast, flexible thermoplastic processing. As lightweighting and durability demands continue to rise, LFTs stand out as a practical and high-performance solution for next-generation engineered parts.

To advance the LFT research toward new topics e.g. bio-based fibers, nano-enhanced matrices and/or hybrid architectures etc, Xplore’s benchtop tools shorten development cycles and seamlessly accelerate the transition from concept to material validation. To explore how micro-compounding can accelerate your LFT formulation and validation work, contact our team.

References

[1] Lee SH, Sung JH, Kim HS, Yoon HG, Lee SG, Kim WN. Electrical percolation and mechanical properties of carbon fiber/long glass fiber/polypropylene hybrid composites. Macromolecular Research. 2013; 21(11): 1232–1239. Link

[2] Cui J, Wang S, Wang S, Li G, Wang P, Liang C. Effects of strain rate on mechanical properties and failure behavior of long glass fiber reinforced polypropylene composites. Polymers. 2019; 11: 2019. Link

[3] Whitfield PD, Blinzler BJ, Ogin SL, Jones FR. The influence of molding parameters on crystallization and molecular degradation in PA6 long fiber reinforced thermoplastics. Polymer Engineering & Science. 2017; 57(5): 482–492. Link