How Continuous Feeders Improve Accuracy in Micro-Compounding?

Published: January 22, 2026 · Reading time: 5 minutes

Introduction

Micro-compounding is increasingly used in polymer research and development to evaluate formulations with minimal material consumption while maintaining industrial relevance. Continuous micro-compounding feeding plays a decisive role in achieving stable, reproducible, and compositionally accurate processing at small scale. However, achieving stable, reproducible, and compositionally accurate processing at small scale requires more than precise temperature and screw control, material feeding plays a decisive role.

Continuous Feeders: A Key Enabler for Micro-Scale Compounding

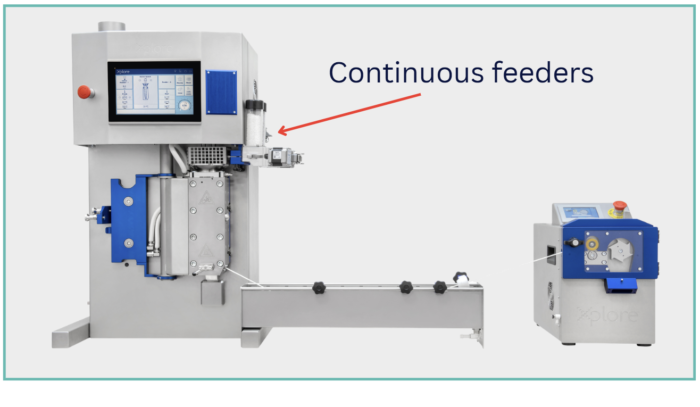

Xplore micro-compounders can operate in both batch and continuous modes depending on their types and application details. While batch operation is well suited for rapid screening, continuous operation becomes essential when processes such as continuous compounding, cast-film, 3D filament extrusion, fibre spinning, or impregnation (composite applications) [1] are targeted. In these cases, continuous feeders form the backbone of the process (Fig. 1).

Figure 1. Xplore Continuous Compounding Line (demonstrated as MC40 in combination with the water bath and Pro-Pelletizer)

Why Continuous Micro-Compounding Feeding Matters

In continuous micro-processing, fluctuations in feed rate directly translate into variations in material composition, melt homogeneity, and final product dimensions. Continuous feeders enable a stable and precisely controlled mass flow, ensuring that material composition remains constant over time and that dimensional variations are minimized.

For researchers, this translates into high reproducibility and reliable comparison between experiments. By eliminating feeding-related variability, the continuous feeding system allows process–structure–property relationships to be studied with greater confidence.

Flexible Feeding Configurations for Research

The Xplore continuous feeding concept allows a single feeder to be operated for the controlled and gentle introduction of a single material (or a pellet premix) into the melt. In addition, two independently controlled feeders can also be mounted on the micro-compounder hopper inlet (Fig. 2), enabling the simultaneous and gentle introduction of different material types into the melt.

A typical setup may consist of:

- A pellet feeder supplying a base polymer or a pre-blended pellet mixture

- A second pellet or powder feeder (powder feeder for introducing powder ingredients such as additives, fillers, pigments, or reinforcing agents)

This modular approach gives researchers the flexibility to adapt the feeding strategy to their formulation, whether working with simple polymer systems or complex multi-component compounds.

These feeding systems enable a wide range of applications, including continuous micro-compounding, melt impregnation, and also fiber/wire coating processes. Practical application examples can be found in the technical notes [2-5].

Figure 2. Examples for Xplore’s Continuous Feeding Concept a) Single Feeder b) Two (Double) Powder Feeders

Continuous Pellet Feeding: Predictable and Linear

In continuous compounding and pelletizing, the Xplore pellet feeder (Fig. 3a) provides predictable and linear dosing behavior. The feed rate increases proportionally with dosing speed over a wide operating range (from 0.1 to 100 rpm) while maintaining a constant and accurate output (Fig. 3b).

The feeder accommodates a wide range of pellet shapes and sizes, ensuring consistent performance across commonly used thermoplastics. This makes it equally suitable for fundamental research and small-scale material production. For advanced control of a single feeder, an optional pressure sensor can be integrated for melt-pressure-based feedback control, further enhancing dosing stability during continuous operation.

Figure 3. a) Pellet feeder image b) Representative flow rate (kg/hr) vs dosing speed (rpm) graph for PLA, PP Pellets (industrial grade)

Powder Feeding: Addressing a Classic Challenge

Powder feeding remains one of the most challenging aspects of continuous compounding. Powders differ widely in bulk density, particle size, cohesion, and moisture sensitivity, often leading to flow issues such as bridging, rat-holing, or compaction, particularly for fine and cohesive materials like pigments or titanium dioxide.

To address this, Xplore offers a single-screw volumetric powder feeder (Fig. 4a) equipped with interchangeable screw geometries and an integrated high-torque agitation system. The built-in agitation prevents bridging and ensures a steady, uniform powder flow, even for materials with poor flow properties.

As with pellet feeding, powder feed rates scale linearly with screw speed, enabling accurate dosing from 0.1 to 100 rpm (Fig. 4b).

Figure 4. a) Powder feeder image b) Representative flow rate (kg/hr) vs dosing speed (rpm) graph for Calcite, Silica, Mg Hydroxide Powders (industrial grade)

Designed for Research Environments

Xplore continuous feeders are designed with laboratory use in mind. Quick-release mechanisms simplify cleaning and material changeovers, minimizing downtime between experiments. Feeding screws can be easily exchanged to match material characteristics, and optional inertization feature allows sensitive materials to be processed under inert gas atmospheres.

The micro-compounder software is pre-configured to control two feeders via the touchscreen interface, allowing straightforward system expansion without the need for additional hardware or software upgrades. Retrofitting options are also available for existing customers. For further details or to discuss retrofit possibilities, please contact our team.

Conclusion

As polymer research increasingly moves toward continuous, data-rich, and reproducible workflows, accurate feeding becomes a critical success factor. Continuous feeders transform micro-compounders into true continuous processing platforms, bridging the gap between laboratory experimentation and industrial processing realities.

References

- Sütcüler YA, Bex GJP, Stupp CA, Kodal M, ten Cate AT, Özkoç G. Lab-scale manufacturing of thermoplastic matrix–continuous carbon fiber filaments for additive manufacturing: melt impregnation, properties of the filaments and its printed composites. Polymer Composites. 2024; 105771. (Link)

- Demonstration of PP/GF-Based LFT Composites Using Laboratory-Scale Coating Line. Technical Note. (Link)

- Continuous Micro-Compounding of Short Carbon Fibre Reinforced PBT Using an Xplore MC 40 & Pro-Pelletizer. Technical note. (Link)

- Micro-tube extrusion for biomedical applications using an Xplore MC 15 HT coupled with a micro-tube die. Technical note. (Link)

- Xplore’s MC 40 micro-compounder in continuous compounding mode. Technical note. (Link)